The Five-Stage Egg Washing Machine Process: From Soaking to Drying

Soaking & Pre-Wash: Temperature-Controlled Solutions to Loosen Organic Contaminants

Most egg washing systems start off with soaking tanks where the water is kept at around 40 to 50 degrees Celsius, which is about 104 to 122 Fahrenheit in regular terms. The heat from these tanks gently works to loosen stuff like poop and bits of feathers stuck on the eggs without making the shells too soft or damaged. What happens next is pretty interesting actually the warm water makes those tiny holes in the eggshells expand by about 3 to 5 microns, which lets dirt come out much easier. This initial soaking step cuts down on how much we need to scrub later on, so there's less chance of creating small cracks in the shells that could let bacteria get inside. Get this right and manufacturers can remove nearly all the dirt from surfaces before even starting the actual brushing process, sometimes getting rid of as much as 95% of what's on there.

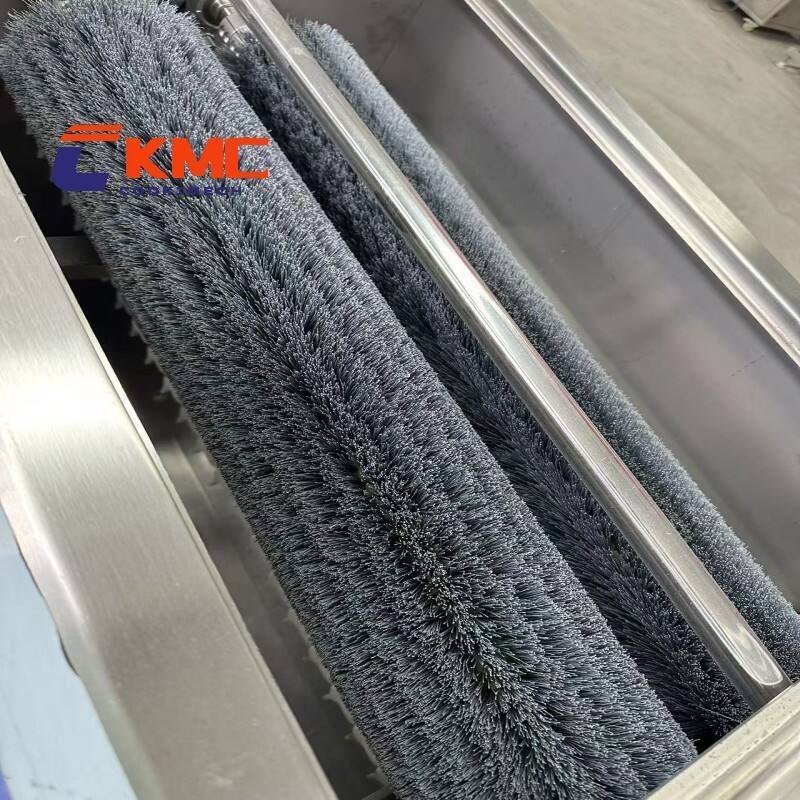

Wash & Rinse: Mechanical Action and Chlorinated Water for Effective Dirt and Fecal Removal

The rotating brushes made for food contact work alongside chlorinated water (around 50 to 200 parts per million) to clean surfaces effectively. Together they form what many call a two-pronged cleaning strategy that knocks out nearly all harmful bacteria like Salmonella according to studies published in reputable food safety journals. Those powerful water jets can reach into tricky spots without making eggs fragile, and after everything gets scrubbed down, there's an instant rinse with drinking water so nothing chemical stays behind. The time spent brushing each egg ranges from about 20 seconds up to maybe 45 seconds total. That gives just enough time to tackle really dirty areas but still keeps production moving fast without damaging the shells themselves.

Sanitize & Dry: Eliminating Residual Bacteria and Preventing Recontamination

Once washed, the eggs go through a quick sanitizing step where they're treated with either quaternary ammonium compounds or peracetic acid. Both options are approved by the FDA and work pretty fast too killing off any remaining bacteria in just about 15 seconds flat. What happens next is equally important drying comes right after using either hot air blowers or infrared technology until the shells have less than half a percent moisture on them. Why does this matter so much? Well research shows that wet eggshells can actually grow three times as many harmful pathogens within an hour alone. That's why modern facilities install those airflow monitoring systems throughout the line. These help keep everything dry evenly, lock in that protective outer layer of the shell, and stop germs from getting back onto the eggs when they move along for packing later on.

Why Drying Is the Critical Final Stage in Every Egg Washing Machine Cycle

Moisture Control: How Drying Inhibits Post-Wash Bacterial Growth on Eggshells

Leftover moisture turns eggshells into breeding grounds for dangerous bacteria such as Salmonella. A study from the Journal of Food Protection back in 2022 found that bacteria levels can jump up ten times in just two hours on wet surfaces, even when they've been cleaned properly. The good news is modern egg washing equipment actually addresses this problem by cutting down surface moisture to below 3%. Scientists have determined this level stops most microbes from multiplying. If we skip this drying process though, everything else done during cleaning basically gets wasted before the eggs reach their packaging stage. So while it might look like just another step at the end, proper drying is really essential for keeping our food safe.

Drying Technologies in Modern Egg Washing Machines: Hot Air, Forced Convection, and Infrared Integration

Three complementary drying technologies deliver speed, consistency, and shell safety:

- Hot Air Systems: Circulate 45–50°C air for 60–90 seconds, balancing efficiency and energy use

- Forced Convection: Uses targeted, high-velocity airflow to accelerate evaporation across irregular surfaces

- Infrared Integration: Electromagnetic waves penetrate moisture pockets beneath the cuticle, cutting drying time by up to 40%

Top-tier systems combine these methods to achieve full dryness in under two minutes–preserving shell integrity while eliminating the primary vector for post-wash recontamination seen in manual or outdated processes.

Egg Washing Machine Compliance: Meeting USDA, FDA, and Global Food Safety Standards

Running an egg washing machine means staying on top of all those food safety rules wherever operations take place. Over in the United States, the USDA has pretty specific requirements about cleaning with approved substances and making sure rinse water stays within certain temps around 40 to 48 degrees Celsius or roughly 104 to 118 Fahrenheit. Meanwhile, the FDA's Egg Safety Rule focuses heavily on preventing Salmonella Enteritidis contamination through various control measures. Looking at international standards, the European Union's Regulation EC Number 589 from 2008 actually lays down concrete restrictions regarding residue levels and overall cleanliness standards that need to be met across member states.

Critical compliance elements include:

- Real-time monitoring of chlorine concentration (50–200 ppm), pH-neutral detergents, and drying performance

- Robust documentation for HACCP validation, sanitation logs, and batch traceability

- Third-party certifications such as ISO 22000 for food safety management systems

Industry data indicates automated egg washing systems reduce USDA inspection violations by 72% versus manual methods–largely due to consistent parameter control, especially in moisture management and sanitizer dosing. Operators must validate equipment cleanability, calibrate sensors quarterly, and maintain audit-ready records to meet evolving global standards.

Commercial Egg Washing Machine Performance: Throughput, Automation, and Precision Parameter Control

In commercial settings, egg washing machine performance rests on three interdependent pillars: high-throughput capacity (8,000–12,000 eggs per hour), advanced automation that cuts manual labor by up to 60%, and granular control over sanitation variables. This integration ensures seamless compliance with USDA, FDA, and international standards while optimizing operational cost-efficiency.

Real-Time Monitoring of pH, Temperature, and Chlorine Levels in Tunnel-Type Egg Washing Machines

Tunnel-type systems deploy integrated sensors to continuously track three key parameters:

- Chlorine concentration, maintained at 100–200 ppm to ensure microbial kill without corrosive overexposure

- Water temperature, held steadily at 40–45°C for optimal cleaning efficacy and shell protection

- pH balance, kept near neutral to avoid calcium carbonate dissolution and preserve structural integrity

As documented in the Poultry Operations Journal (2023), this automated oversight sustains a 98.6% shell integrity rate–directly lowering breakage and waste. By replacing error-prone manual checks, real-time monitoring mitigates contamination risks inherent in traditional washing and strengthens overall food safety assurance.

FAQ

What are the main steps in the egg washing machine process?

The egg washing process typically involves soaking and pre-washing, washing and rinsing, sanitizing and drying, each designed to effectively remove dirt, bacteria, and prevent recontamination.

Why is drying an important stage in egg washing?

Drying is crucial because it prevents bacterial growth on wet eggshells. Proper drying ensures that moisture does not provide a breeding ground for pathogens like Salmonella.

What compliance standards do egg washing machines need to meet?

Egg washing machines must adhere to USDA, FDA, and international standards, focusing on using approved cleaning substances, monitoring temperatures, and ensuring effective drying and sanitation.

How do modern egg washing machines enhance performance?

Modern machines enhance performance through high-throughput capacity, automation, and precise control over sanitation variables, ensuring compliance and operational efficiency in egg processing.

Table of Contents

- The Five-Stage Egg Washing Machine Process: From Soaking to Drying

- Why Drying Is the Critical Final Stage in Every Egg Washing Machine Cycle

- Egg Washing Machine Compliance: Meeting USDA, FDA, and Global Food Safety Standards

- Commercial Egg Washing Machine Performance: Throughput, Automation, and Precision Parameter Control

- FAQ