No. 1, Hujiagou, Zhucheng City, Weifang City, Shandong Province,China +86-15814571173 [email protected]

In the UK, where the dairy industry is highly developed, consumers have an extreme pursuit of the quality, taste, and safety of mozzarella cheese. Recently, Zhucheng Cookimech Co., Ltd. in Shandong Province (hereinafter referred to as "Cookimech") has successfully put into production a fully - automatic mozzarella cheese production line tailored for a UK dairy enterprise. With its precise control of raw material characteristics, meticulous polishing of process details, and deep compliance with EU standards, it has become a "new benchmark" in the local high - end dairy product processing field, injecting modern vitality into traditional cheese production.

The UK dairy market is known for its strict quality standards and diverse consumer demands. As a core ingredient in foods such as pizza and salad, the "stringiness", "richness of milk flavor", and "shelf - life stability" of mozzarella cheese are key indicators to measure product competitiveness. Previously, the UK dairy enterprise used semi - automated production equipment, which had problems such as low raw material utilization, uneven cheese texture, and significant batch - to - batch differences, making it difficult to meet the procurement requirements of the high - end catering market and chain brands. To break through the development bottleneck, the enterprise screened equipment suppliers globally and finally chose to cooperate with Cookimech, attracted by its technical accumulation and customized service capabilities in the food machinery field.

Cookimech formed a special team consisting of food technology experts, mechanical engineers, and EU standard consultants. It took 3 months to complete on - site research and solution design. In view of the characteristics of using Holstein milk as the main raw material in the UK and the prominent demand for products without added preservatives, a fully - intelligent mozzarella cheese production line was tailored, realizing "unmanned" operation from raw milk treatment to finished product packaging, with the whole process controllable and traceable.

In the raw milk pretreatment process, the low - temperature pasteurization system equipped on the production line adopts a precise temperature - control process of "72℃/15 seconds". While killing harmful microorganisms, it maximally retains the active nutrients and natural milk aroma in the milk. The online milk component analyzer installed on the equipment can monitor the milk fat and protein content in real - time. By automatically adjusting the standardization system, it ensures the stable composition of raw milk, laying the foundation for the consistency of cheese quality. Considering the rainy climate and high air humidity in the UK, the raw material storage tank is designed with "constant temperature and humidity", with the temperature controlled at 4℃±0.5℃ and the humidity maintained below 60% to prevent the raw milk from spoiling.

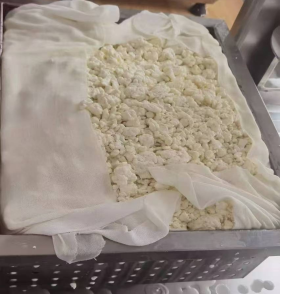

The curdling and cutting processes are the core procedures that determine the texture of mozzarella cheese. The intelligent curdling system developed by Cookimech precisely controls the amount of rennet added, the temperature (32℃±0.3℃), and the standing time through a PLC controller, enabling the curd to form a uniform network structure and creating conditions for the subsequent stretching process. In the cutting process, "ultrasonic cutting technology" is used to replace traditional blade cutting. The cut is smooth without debris, and the error in curd size is controlled within 0.2mm, solving problems such as "excessive whey loss" and "loose texture" caused by traditional cutting.

The stretching and shaping processes directly affect the "stringing performance" of the cheese. The scalding and stretching unit of the production line adopts a "double - screw synchronous stretching" design. Through a hot - water circulation system at 63℃±1℃, the curd reaches the best ductility. With an adjustable stretching rate (3 - 5 meters/minute), the cheese forms a dense and elastic organizational structure. Tests show that the mozzarella cheese produced by this process can have a stringing length of more than 30cm, and its fracture toughness is excellent, far exceeding the industry average. In the shaping stage, the "vacuum shaping mold" can produce various shapes such as balls, blocks, and strips according to customer needs, with an error controlled within ±1g, meeting the usage requirements in different scenarios.

To comply with the EU's strict restrictions on food additives, the production line has carried out special innovations in the ripening and preservation processes. The "low - temperature slow - ripening" process is adopted. The cheese is placed in a ripening warehouse at 12℃±1℃ and a humidity of 85%±2%, and the flavor is slowly released through natural fermentation, replacing the traditional method of relying on additives to extend the shelf - life. In the packaging stage, a "modified atmosphere packaging system" is introduced, filling a mixed gas of 70% carbon dioxide + 30% nitrogen to inhibit the growth of microorganisms, extending the shelf - life of the cheese without added preservatives to 45 days, a 50% increase compared with the traditional process.

The compliance design of the entire production line runs through. From the equipment material to the operation process, it strictly follows the EU CE certification, the UK BRC food standard, and dairy - specific regulations. All parts of the equipment in contact with food are made of 316L stainless steel, with a surface roughness of Ra≤0.8μm, meeting the EU 10/2011 food - contact material standard. The cleaning system uses "CIP in - place cleaning", alternating acid - base flushing + high - temperature sterilization (85℃/30 minutes) to ensure thorough equipment hygiene. Production data is uploaded to the cloud in real - time, and a "from pasture to shelf" full - chain report that meets EU traceability requirements can be generated, easily coping with random inspections by regulatory authorities.

In addition, the production line also shines in terms of energy - saving and intelligence. Through a waste - heat recovery system, the steam heat energy from the pasteurization process is used for the scalding and stretching process, reducing energy consumption by 22%. The intelligent control panel supports multi - language operations such as English and Welsh, and has a built - in AI process optimization module that can automatically adjust process parameters according to the composition of raw milk. New employees can operate independently after one week of training.

According to customer feedback, after the production line was put into production, the raw material utilization rate of mozzarella cheese increased from 82% to 95%, unit energy consumption decreased by 22%, and the batch qualification rate jumped from 88% to 99.7%. Due to its "stable stringing performance" and "naturally rich milk flavor", the product has successfully entered the procurement list of the London High - end Catering Association and reached long - term cooperation with several international pizza chain brands, with a 30% increase in the product premium space. "Cookimech's production line is not just a set of equipment but a 'quality assurance system'," said the production director of the enterprise. "It has enabled us to gain the right to speak with 'hard power' in the fierce market competition."